Product Description

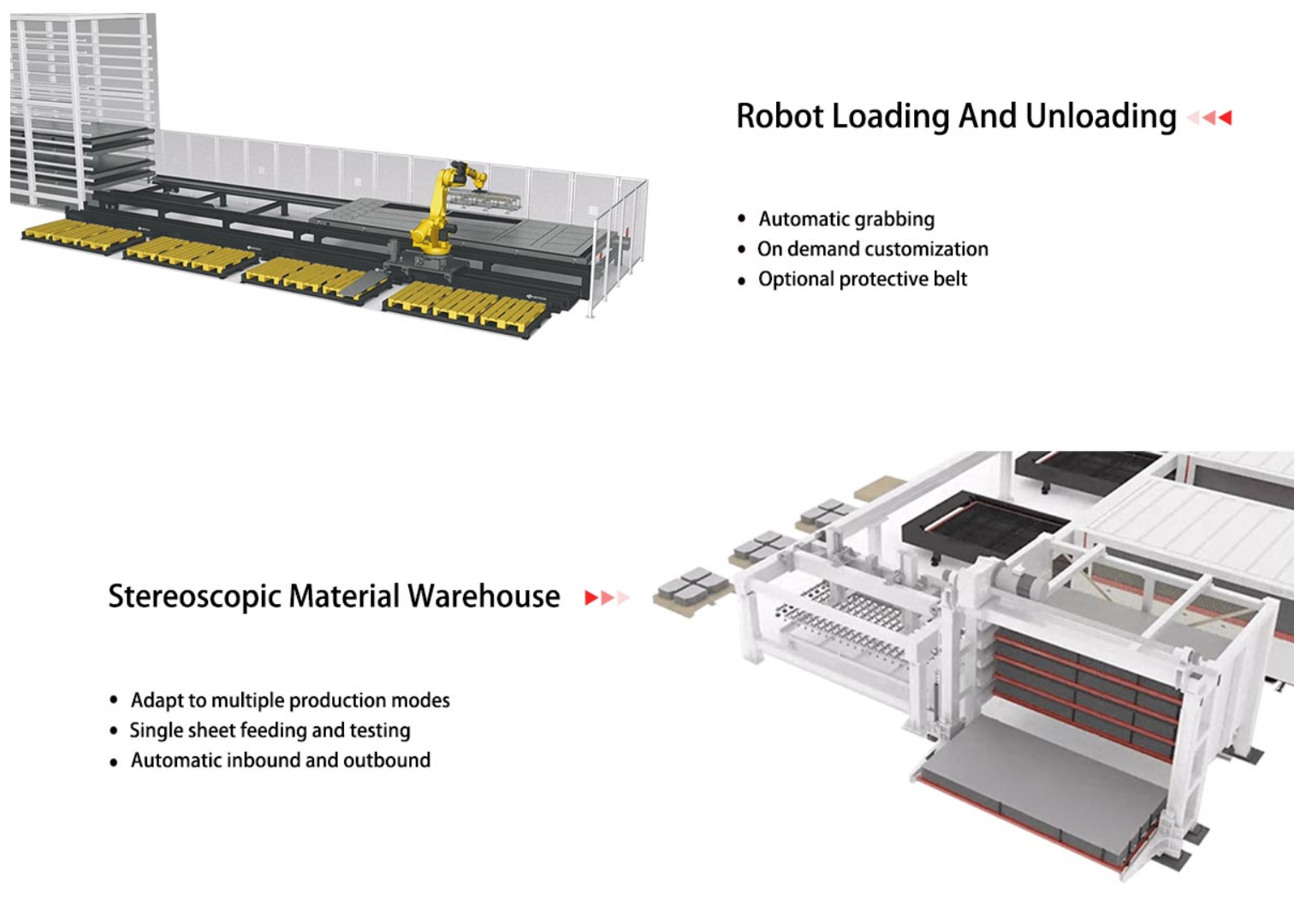

HGTECH Laser Cutting Flexible Production Line includes multiple sets of laser cutting automated material warehouses

Each set of laser cutting automated material warehouse consists of a material warehouse system, an automatic loading and unloading system, a production line operation, and a monitoring system, which can be adapted to 1-3 laser cutting machine tools.

The automated material warehouse can automatically store and retrieve materials without direct human intervention.

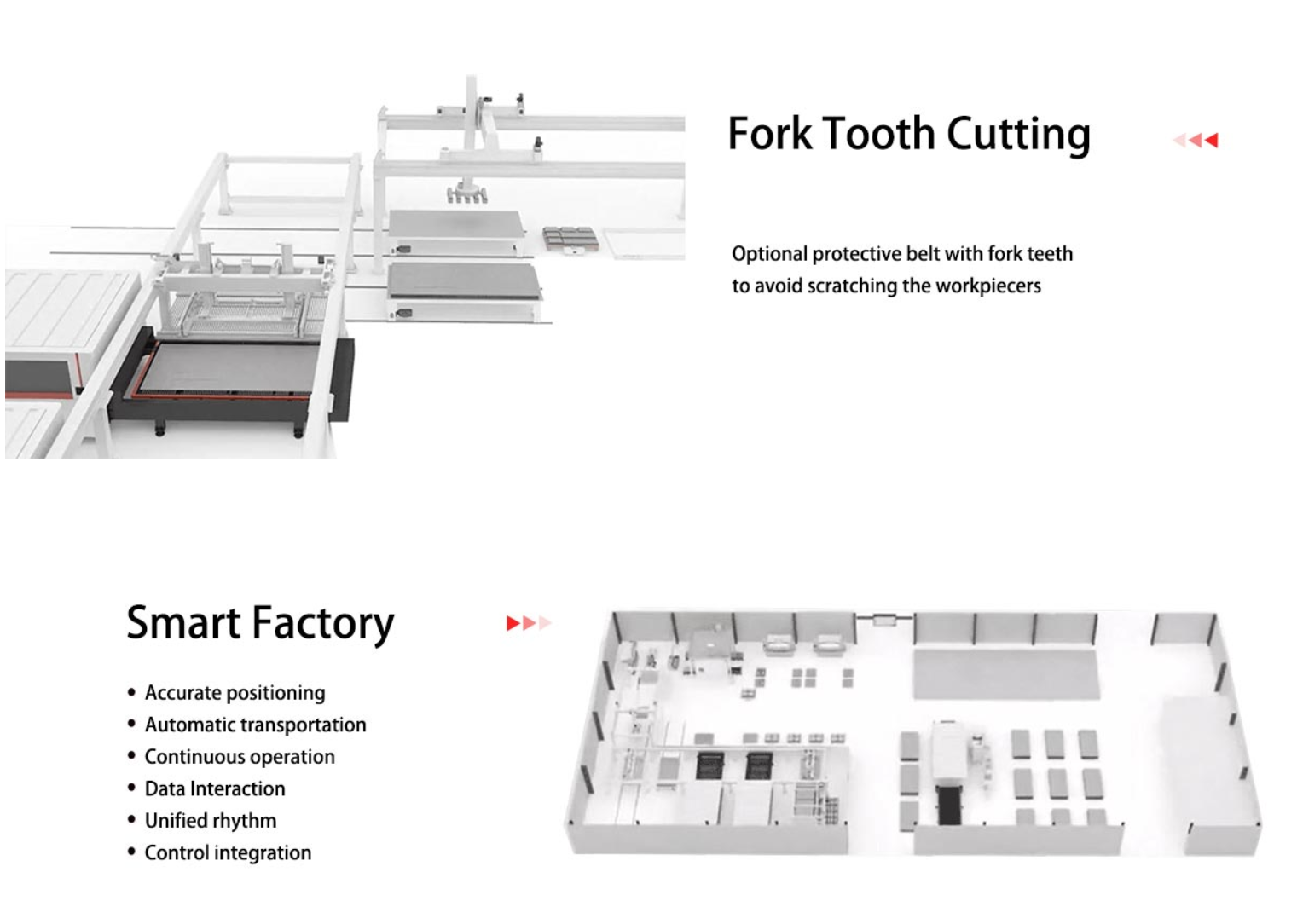

Modular design / Intelligent Control / Achievable MES System Network

Management

-Single Suction / Automatic Split / Laser Cutting / Laser Marking

-Automatic Loading or Unloading / Sorting / Stacking /In or out of the

Library / Storage / Transfer / Waste Cutting

Extended Functions